Call Us Today!

(812) 418-8111

Meeting All of Your Production and Assembly Solution Needs

ISO 9001: 2015 Certified

EQUIPMENT

Check out our new waterjet!OMAX 60120 Precision JetMachining Center

EQUIPMENT

Item Description:

- CNC Lathe - Daewoo Lynx 220L - 8" Capability

- CNC Lathes (2) - 0-5" capability Akebono MINC-26 (X6)

- CNC Mill - Hyundai-Kia VX440

- CNC Mill - LK TT510

- CNC Mill- Okuma MC-4VAE 9588

- Automatic Horizontal Bandsaw- Hyd-Mech H-10A 10" x 10" capacity

- Manual Mill - Sharp Knee Mill HMV W/ X&Y Digital readouts

- *NEW* Kent Surface Grinder - 12" X 30"

- Surface Grinder- Sunmax - 8" X 16"

- Horizontal Bandsaw- Jet HVBS-7MW

- Cut-Off Saw- Milwaukee 14" Abrasive cut-off machine

- Air Compressor- Quincy QGS-15

Gauges:

- Mitutoyo Digital dual column height gauge 18" (450 mm)

- Mitutoyo Digital dual column height gauge 12"

- Mitutoyo 0-6 inch Calipers- Dial and Digital - 8 sets

- Starrett Straightedge No. 385

- Gauge Pin 8 Pin Gauge sets

- Gauge Blocks 3 Gauge Block Sets

- Gauge Balls 1 Gauge Ball Set

- Verniers Mitutoyo 0~40 Inches

- Surface Plates Granite Surface Plate with Steel Stand and Wheels

- Browne & Sharpe Quad Cut

- Browne & Sharpe Double Cut

WATER JET

Omax 55100 & 60120

- Precision machining: From prototypes to production runs in sizes up to 6’ x 12’.

- Cuts complex flat parts out of materials including metal, plastic, glass, ceramic and composites directly from a CAD drawing or .DXF file.

- Does not create heat affected zones - No heat-affected zone or thermal damage normally associated with laser or plasma cutters.

TURNING

Our turning centers are designed for long-term high accuracy and superior surface finishes.

Daewoo Lynx

- Bar Capacity: 2.625 " / 66.7 mm

- Axis:2

- Fanuc I CNC Control

- Up to 12" Diameter

- Tailstock, Parts Catcher and Tool Setter

- Spindle Speeds 40 - 4,000 RPM

- X Axis Travel 6.9"

- Z Axis Travel 21.7"

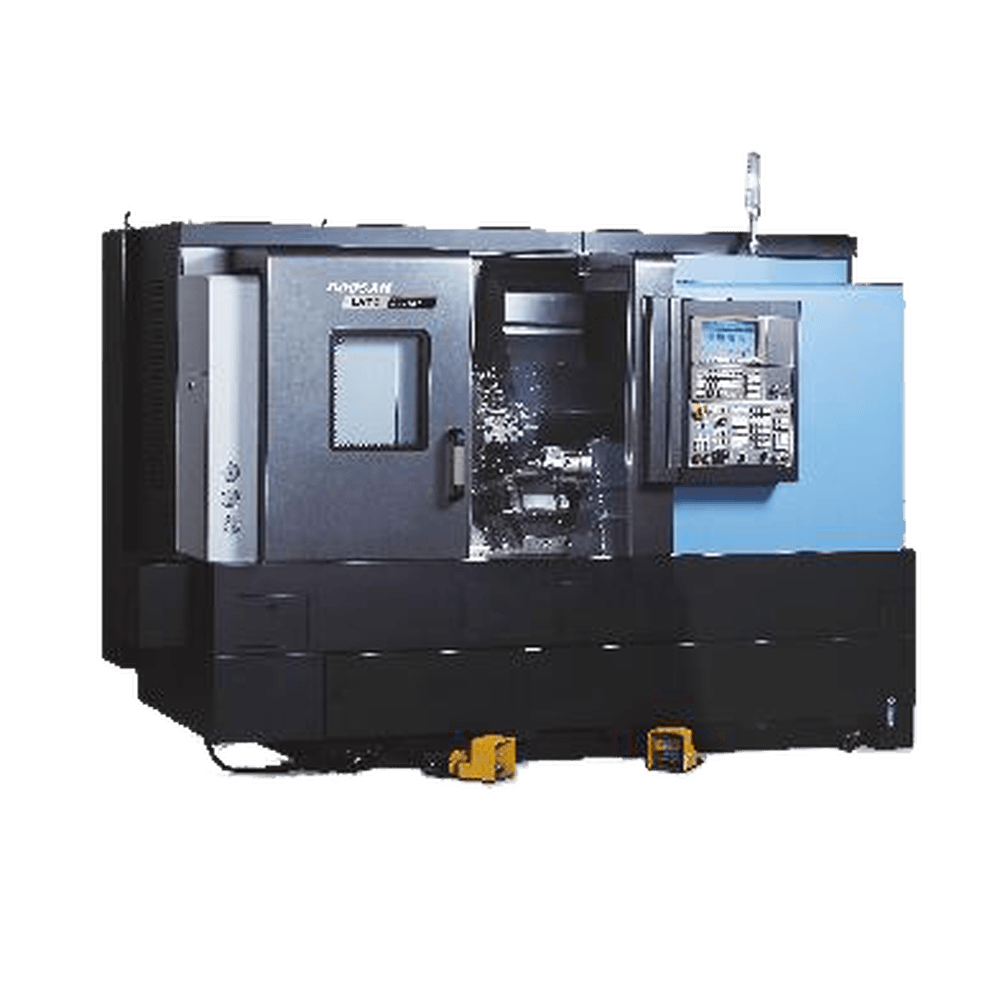

Doosan Lynx 2100SLYB

- Live tool lathe with sub-spindle Y-Axis

- Fast traverse rates minimize non-cutting time

- Bar Capacity: 2.625"/66.7 mm

- Max Turn Diameter: 11.8"

- X-Axis Travel: 8.07"

- Z-Axis Travel: 22"

MILLING

Machining Center accomplished super power heavy-duty cutting with high accuracy, high rigidity, and high precision performance, based on minimized heat

LK

- 3-Axis Vertical Drilling and Tapping Machine w/ Haridinge 4axis indexer.

- The spindle runs in 4 high precision angular contact ball bearings assuring long-term accuracy and maximum rigidity and stability.

- Max Spindle Speed 10000rpm

- Rigid Tapping

- Table Size L:23.600 X W:15.700

- Max. Weight Of Work Piece 550

Hyundai-Kia Vertical Machining

- Table Size Mm(In): 1,000x460(39.4"X18.1")

- Max Load On Table Kg(Lb.): 600(1,323)

- Spindle Speed: 12,000 Rpm

Okuma MC 4 VAE

- 3-Axis Vertical Milling Machine

- X-Axis: 650 Mm Y-Axis: 410 Mm Z Axis: 450 Mm Table Size: 1000x410 Mm

- Maximum Table Load 1,100 Lbs.

Call Us Today At ♦ (812) 418-8111

ADDRESS

Lear Machining & Waterjet

4056 N Long Rd

Columbus, IN 47203

Phone Number:

(812) 418-8111

IN BUSINESS SINCE 2010

BUSINESS HOURS

Mon - Fri: 08:00 AM - 04:30 PM

Sat - Sun: Closed

Appointments Available

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy